JST Industry

Provides Professional CNC Brass Machining Services

Advantages of Brass Machining

Brass has an irreplaceable place in many industries as a material with excellent mechanical properties and beautiful surfaces. Here are some of the significant advantages of choosing brass for CNC machining:

Good Mechanical Properties

Brass is easy to machine, has good ductility and fatigue resistance, and is suitable for manufacturing precision parts.

Aesthetically Pleasing Surfaces

The natural color and luster of brass makes it very popular for decorative applications.

Corrosion Resistance

Brass has good resistance to atmospheric corrosion and is suitable for environments requiring high corrosion resistance.

Thermal Conductivity

The thermal conductivity of brass is suitable for parts that require heat dissipation, such as musical instruments and certain electronic devices.

Brass Properties and Applications

JST Industry offers CNC machining services for a wide range of brass materials to meet the specific needs of different industries with regard to material properties.

Wear Resistance

The wear resistance of brass makes it ideal for bearings and gears.

Musical Instrument

Due to its acoustic properties, brass is widely used in the manufacture of musical instruments such as trumpets and brass instruments.

Valves and Fittings

The corrosion resistance and strength of brass make it an ideal material for valves and fittings.

Electrical Components

The electrical conductivity of brass makes it suitable for connectors and terminals in the electrical and electronics industry.

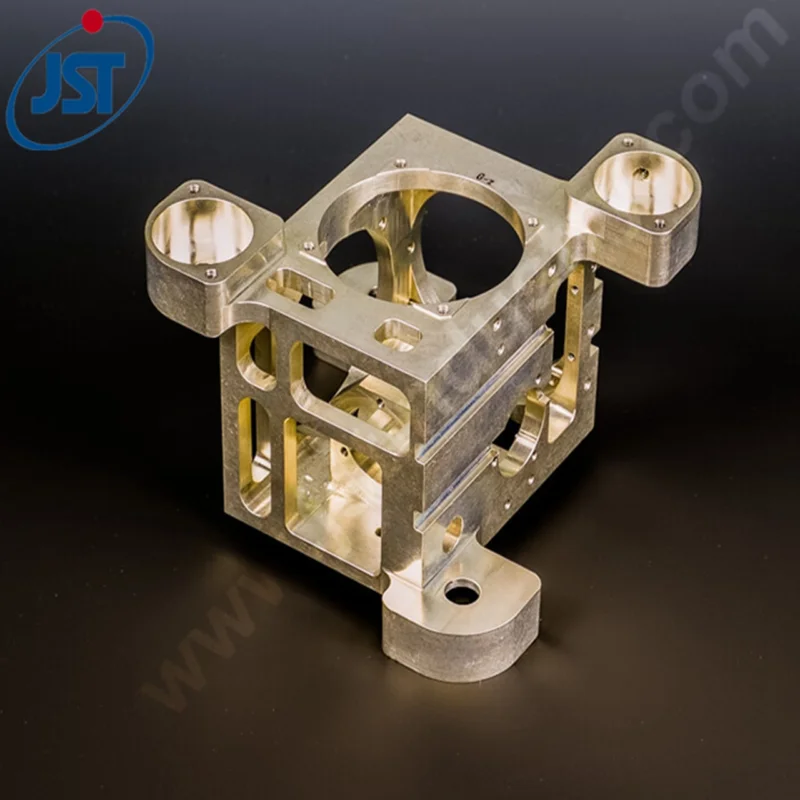

CNC Brass Machining Parts

Brass Surface Treatments and Finishing

JST Industry offers a variety of finish options after CNC machining brass parts to enhance the appearance, durability and functionality of the product.

Polishing: From rough polishing to mirror polishing, different glossy surface finishes are available to meet the diverse needs of our customers.

Plating: Includes nickel plating and chrome plating to improve the wear and corrosion resistance of brass parts.

Passivation: Enhance the corrosion resistance of brass through passivation treatment for more demanding applications.

Brass Machining Cases and Feedback

Swiss Watch Manufacturer

“When looking for a partner that could accurately machine watch parts, we chose JST Industry.Their mastery of machining brass materials and strict attention to detail has resulted in industry-leading precision and durability of our watch movement components.JST Industry’s professional service and commitment to quality have earned our products earn an excellent reputation in the high-end market.”

Automotive Sensor Manufacturer, Stuttgart, Germany

“For the precision brass components of our automotive sensors, JST Industry has demonstrated excellent machining capabilities. Their precise control of tolerances and deep understanding of material properties ensures the consistency and reliability of our products. In addition, the rapid prototyping services provided by JST Industry have significantly shortened our development cycle and enhanced our competitiveness in the marketplace.”

Medical Device Company, Boston, USA

“In the medical device field, where product accuracy and surface quality are of paramount importance, JST Industry’s CNC brass machining services meet our stringent requirements and their parts meet our high standards for dimensional accuracy and surface finish. Their dedicated technical support team was extremely helpful during the project, ensuring the successful development of our product.”

High-end musical instrument manufacturer, Tokyo, Japan

“Making high quality brass instruments requires fine machining of the brass material.JST Industry not only provides high quality brass material, but also through their precise CNC machining techniques, our instruments are of state of the art standard in terms of sound quality and appearance. Their customization and dedication to craftsmanship have earned our instruments high marks among professional musicians.”

FAQs

Q: I am designing a new product that requires CNC machining to create a prototype and final product. How do I select the most suitable material for CNC machining for my project?

A: At JST Industry, we understand that choosing the right CNC machining material is critical to product design. You should first consider the scenario in which your product will be used, including the required mechanical properties, temperature resistance, corrosion resistance, and cost-effectiveness. We offer a wide range of material options including, but not limited to, aluminum alloys, stainless steel, brass, various alloys, and many plastics. Our team of experts can assist you by selecting the most appropriate material for your specific needs and provide expert design optimization advice to ensure an efficient and cost-effective CNC machining process.

Q: I would like to know how the selection of different materials in CNC machining process affects the final machining cost?

At JST Industry, we recognize that material selection has a significant impact on CNC machining costs. The type of material, difficulty of machining, and market availability all affect its price. For example, steel is widely used due to its lower cost, while titanium alloys and certain advanced alloys are more expensive due to their higher material cost and machining difficulty. In addition, the machinability of the material also affects the cost, e.g. aluminum alloys are usually less expensive due to their ease of machining. Our quoting system takes all of these factors into account to ensure you get the most accurate cost estimate.

Q: What are some design practices that can help me reduce machining costs when designing CNC machined parts?

Q: I have stringent requirements for accuracy in my products, what tolerances can be achieved with CNC machining and how does this affect the quality of the final product?

A: At JST Industry, our CNC machining services are capable of meeting extremely high tolerances, often to ±0.01mm, thanks to our advanced machining equipment and strict quality control processes. This high-precision machining capability ensures consistency and reliability of parts, which is especially important for assemblies that require high-precision fit. Our quality assurance system includes multiple inspections and calibrations to ensure that each part conforms to the customer’s design drawings and tolerances, thus guaranteeing the quality of the final product.